Lubricants for cement industry

Applications

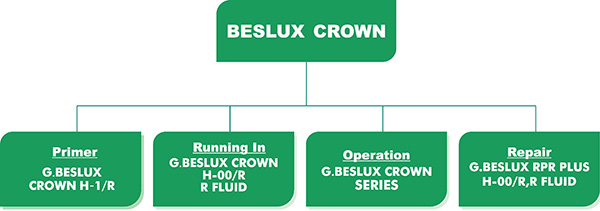

Lubricants for cement industry BESLUX CROWN Open Gear Lubricants Series

The lubrication of vast crown-gear mills and ovens activity in the cement industry is one of the main applications for which Brugarolas has accumulated such broad experience.

We have developed a wide range of lubricants with high technology: G. Beslux Crown. With this, Brugarolas is present in a large amount of cement companies at the global level, increasing its production thanks to a high level of efficiency in lubrication systems.

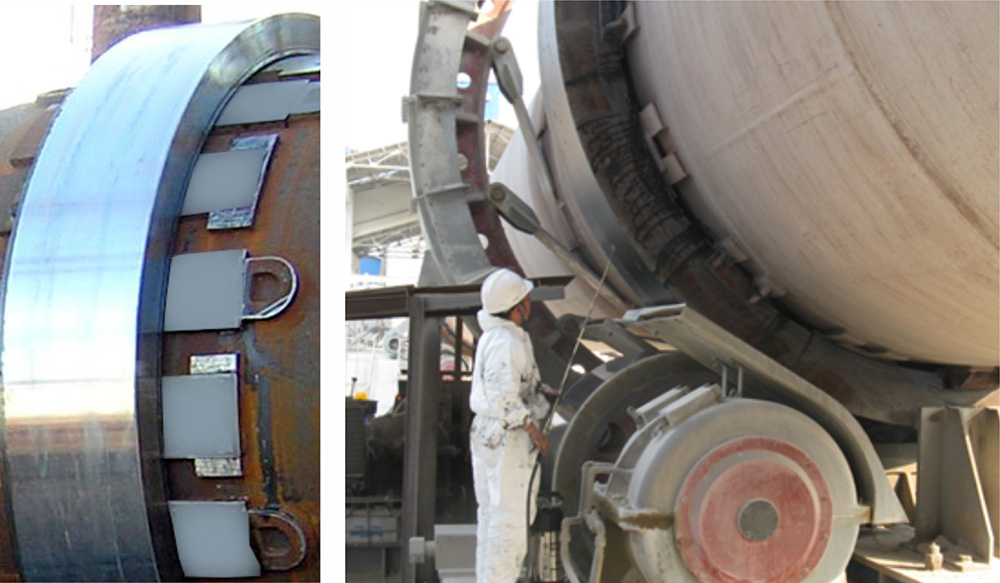

Lubrication of Rotary Kiln

Lubrication of Rotary Kiln Lubrication of Kiln Belt and Base Plate

Generally, the thermal expansion rate and rigidity of the rotary kiln body and the kiln belt are different, so the inner diameter of the kiln belt is designed to be larger than the outer diameter of the kiln body. In this way, the contact surface between the base plate and the kiln belt will produce rolling displacement during rotation, and the normal rolling displacement is related to the diameter difference between the kiln body and the kiln belt.

Recommended Products

G. BESLUX GRAFOL HT PASTE is a high-temperature grease rich in graphite solid lubricant. When the wheel belt base plate is initially installed or replaced, it is pre-coated on the base plate and the contact friction surface to effectively protect the base plate from wear.

The operating lubricant BESLUX GRAFOL 320 is a high-temperature synthetic oil containing solid lubricant graphite. With the rotation and gravity of the rotary kiln, the base oil drives the solid lubricant to flow between the inner side of the kiln belt and the base plate, forming a good oil film. The base oil volatilizes completely at high temperature. The dry film of the solid lubricant is stabilized to 600 °C, and the solid lubricant is evenly brought to the inner surface of the wheel belt to lubricate the friction parts, reducing abnormal wear.

The operating lubricant BESLUX GRAFOL 150 (used for automatic spraying lubrication system) is a synthetic high-temperature kiln belt lubricant, which is specially designed for the automatic oil injection device of the belt on the rotary kiln of the cement plant. High temperature resistance, wear reduction and easy spraying. It is composed of special graphite containing stabilizer as support, which will evaporate at 250 ºC and leave a dry lubricant film that can withstand up to 600 ºC.

Support Roller Bearing

The supporting roller bearing bears the weight of the whole rotary kiln. The bearing bush is generally made of Babbitt alloy, so there are special requirements for the copper corrosion characteristics of oil products. The materials used for the bearing bush and the complex working conditions during the kiln operation change. The bearing capacity of the three pairs of supporting rollers will bear the impact load.

Generally, forced lubrication is adopted for supporting roller bearing bush, and its lubrication principle is dynamic pressure lubrication. Therefore, appropriate viscosity is required to form an oil film to float the journal, and excellent extreme pressure performance is also required.

BB SINTER 3100

BESLUX CROWN 150 OG PLUS

Block-Wheel Bearing

Lubrication of Block-Wheel Bearing

Grease lubrication: G.BESLUX SULPLEX EH-2/G

Oil lubrication: BESLUX SINTER 1500 CH