Lubricants for cement industry

Applications

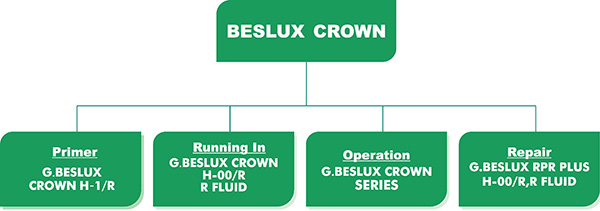

Lubricants for cement industry BESLUX CROWN Open Gear Lubricants Series

The lubrication of vast crown-gear mills and ovens activity in the cement industry is one of the main applications for which Brugarolas has accumulated such broad experience.

We have developed a wide range of lubricants with high technology: G. Beslux Crown. With this, Brugarolas is present in a large amount of cement companies at the global level, increasing its production thanks to a high level of efficiency in lubrication systems.

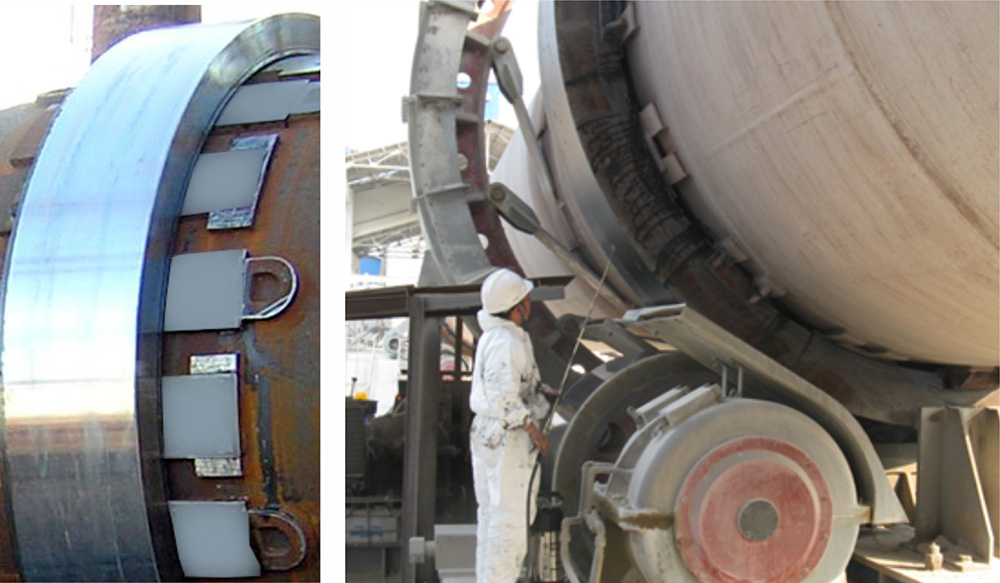

Lubrication of Rotary Kiln

Lubrication of Rotary Kiln Lubrication of Kiln Belt and Base Plate

Generally, the thermal expansion rate and rigidity of the rotary kiln body and the kiln belt are different, so the inner diameter of the kiln belt is designed to be larger than the outer diameter of the kiln body. In this way, the contact surface between the base plate and the kiln belt will produce rolling displacement during rotation, and the normal rolling displacement is related to the diameter difference between the kiln body and the kiln belt.

Recommended Products

G. BESLUX GRAFOL HT PASTE is a high-temperature grease rich in graphite solid lubricant. When the wheel belt base plate is initially installed or replaced, it is pre-coated on the base plate and the contact friction surface to effectively protect the base plate from wear.

The operating lubricant BESLUX GRAFOL 320 is a high-temperature synthetic oil containing solid lubricant graphite. With the rotation and gravity of the rotary kiln, the base oil drives the solid lubricant to flow between the inner side of the kiln belt and the base plate, forming a good oil film. The base oil volatilizes completely at high temperature. The dry film of the solid lubricant is stabilized to 600 °C, and the solid lubricant is evenly brought to the inner surface of the wheel belt to lubricate the friction parts, reducing abnormal wear.

The operating lubricant BESLUX GRAFOL 150 (used for automatic spraying lubrication system) is a synthetic high-temperature kiln belt lubricant, which is specially designed for the automatic oil injection device of the belt on the rotary kiln of the cement plant. High temperature resistance, wear reduction and easy spraying. It is composed of special graphite containing stabilizer as support, which will evaporate at 250 ºC and leave a dry lubricant film that can withstand up to 600 ºC.

Support Roller Bearing

The supporting roller bearing bears the weight of the whole rotary kiln. The bearing bush is generally made of Babbitt alloy, so there are special requirements for the copper corrosion characteristics of oil products. The materials used for the bearing bush and the complex working conditions during the kiln operation change. The bearing capacity of the three pairs of supporting rollers will bear the impact load.

Generally, forced lubrication is adopted for supporting roller bearing bush, and its lubrication principle is dynamic pressure lubrication. Therefore, appropriate viscosity is required to form an oil film to float the journal, and excellent extreme pressure performance is also required.

BB SINTER 3100

BESLUX CROWN 150 OG PLUS

Block-Wheel Bearing

Lubrication of Block-Wheel Bearing

Grease lubrication: G.BESLUX SULPLEX EH-2/G

Oil lubrication: BESLUX SINTER 1500 CH

Lubrication of Vertical Mill

Central lubrication system is generally adopted for roller bearing lubrication of vertical mill, main reducer lubrication and hydraulic oil.

During the operation of the roller bearing under high load, and environment is accompanied by high temperature, dust, and shock vibration, thus it is required that the lubricating oil has good high-temperature resistance.

| Lubricating Objects | Position | Lubricants | Lubrication Method |

| Hydraulic Station | Main roll hydraulic station | BESLUX FLUID DRIVE HM 46 | Centralized lubrication |

| Roll-over hydraulic station | Centralized lubrication | ||

| Reducer | Main reducer | BESLUX GEAR XPM Series BESLUX GEARSYNT XP Series | Centralized lubrication |

| Slow drive reducer | Centralized lubrication | ||

| Decelerator of powder concentrator | Centralized lubrication | ||

| Feeder reducer | Centralized lubrication | ||

| Oil Station | Vertical mill roller | BESLUX GEARSYNT XP Series BESLUX SINCART W Series | Centralized lubrication |

| Bearing | Bearing of powder concentrator | G. BESLUX PLEX EH-2/G G. BESLUX SULPLEX EH-2/G | Automatic lubrication |

| Bearing of powder concentrator | Manual lubrication | ||

| Feeder bearing | Manual lubrication | ||

| Roller bearing sealing | G. BESLUX FLUOR H-2 | Manual lubrication |

Lubrication of Air Compressor Requirements of excellent compressor oil

● Very low residue and carbon residue

● Good waterproof performance

● Extend the oil change (or refueling) interval

● Lower flammability

● Lower volatility

● Excellent strength of oil film, less friction

| Lubricants | Compressor Type | Specification | |||

| Piston | Screw | Blade | ISO VG | Base Oil Nature | |

| BESLUX AIR CRK 46 | V | 46 | Semi-Synthetic | ||

| BESLUX ULTRASINT 46 | V | 46 | Fully Synthetic/PAO | ||

| BESLUX AIR SPEED IRS | V | 46 | PAG/POE | ||

Lubrication of Roller Press

The new energy-saving cement grinding equipment can replace the ball mill pre grinding system with high energy consumption and low efficiency, and reduce steel consumption and noise. The roller press has outstanding grinding efficiency and excellent energy-saving effect, and has been widely used in domestic cement grinding system.

Operating Properties

● Heavy load

● Low speed

● Dust

● Impact load

Lubrication Requirements

●Good oil film thickness and strong adhesion.

(Base oil viscosity 1500cSt)

●Strong bearing capacity under extreme pressure.

(Four-ball welding load >400kg)

●Impact load resistance, requiring additional

solid lubrication protection. (If graphite is contained)

●Good pumping performance, stable structure, and wide range of working temperatures.

Features

● High drop point ● Good pumpability ● Heavy load resistance ● High wear resistance

Approval and Recommendation

by REEL, KHD. HUMBOLDT WEDAG POLYSIUS, F.L. SMIDTH, LEE JUN, CITIC HMC and SINOMA.

Lubrication Points of Roller Press

| Position | Lubricants |

| Main Bearing | G.BESLUX PLEX EH-1/G G.BESLUX PLEX EH-2/G |

| Hydraulic System | FLUID DRIVE HM-46 FLUID DRIVE HM-68 |

| Planetary Gearbox Main Reducer | BESLUX GEAR XPM 320 BESLUX GEAR ET 220/320 (Red, leak proof, high wear resistant gear oil) BESLUX GEARSYNT XP 320 |

| Gear Coupling | G. BESLUX SULPLEX EH-1/G G. BESLUX GFG |

| Main Motor Bearing | G.A. PLEX 2 G. BESLUX SULPLEX M-2 ROJA G. BESLUX KOMPLEX ALFA II |

Lubrication of Raw Material Crusher

Raw material crusher is one of the most important equipment in the raw material preparation process of cement plant. All ores can be supplied for subsequent production only after being crushed by raw material crusher.

The key lubrication point of the raw material crusher is the main bearing of the crusher. Its working condition is low speed (about 300 rpm), heavy load, strong impact load, and it also bears serious dust pollution, rain invasion and other problems. Therefore, it is necessary to select products with high viscosity, strong bearing capacity and preferably graphite solid lubricant for lubrication so as to effectively protect the normal operation of the bearing.

| Position | Lubricants | Lubrication Method |

| Main Motor Bearing | G.A. PLEX 2 G. BESLUX SULPLEX M-2 PLUS G. BESLUX KOMPLEX ALFA II | Manual lubrication |

| Main Reducer | BESLUX GEAR XPM 320 | Centralized lubrication |

| Main Bearing | G. BESLUX PLEX EH-2/G G. BESLUX SULPLEX EH-2/G G. BESLUX SULPLEX H-2 PLUS | Centralized lubrication |

Lubrication of Grate Cooler

Grate cooler is one of the important equipment for cement clinker production. High temperature cement clinker is rapidly cooled here. The movable grate plate can be driven by hydraulic drive and mechanical drive. Since the equipment has been working at high temperature for a long time, it is necessary to use high temperature resistant grease.

G. BESLUX SULPLEX H-2 PLUS the calcium sulfonate complex grease is used for high temperature and heavy load, and has excellent water resistance, good sealing and aging resistance. It is especially recommended for the lubrication of grate cooler.

| Grate Cooler Draught Fan Motor Bearing | G. BESLUX SULPLEX H-2 PLUS (Low speed bearing)G. BESLUX KOMPLEX ALFA II (High speed bearing)G. BESLUX SULPLEX M-2 PLUS G. BESLUX SULPLEX M-2 ROJA G.A.PLEX 2 | Good high temperature and mechanical stability, strong anti-wear bearing capacity, effectively prolong bearing life and lubrication cycle. |

| Crusher Bearing | G. BESLUX SULPLEX H-2 PLUS |

G. BESLUX CROWN – Graphite Fluid Grease OG Type

| Product | G. BESLUX RPR PLUS (Online Repair) | G.BESLUX CROWN H-1/R | G.BESLUX CROWN H-00/R | G.BESLUX CROWN R FLUID | G.BESLUX CROWN H-0 PLUS | G.BESLUX CROWN L FLUID | G.BESLUX CROWN EL FLUID |

| Color | Ivory | Black | Black | Black | Black | Black | Black |

| Base Oil | Mineral | Mineral | Mineral | Mineral | Semi-synthetic | Semi-synthetic | Semi-synthetic |

| Thickener | Lithium | Aluminium complex | Aluminium complex | Aluminium complex | Aluminium complex | Aluminium complex | Aluminium complex |

| NLGI Grade | 2 | 1 | 00 | 000 | 0 | 000 | 000 |

| Drop Point | >180°C | >190°C | >190°C | >190°C | >190°C | >200°C | >200°C |

| Welding Load | N.A. | >800Kg | >800Kg | >800Kg | >800Kg | >800Kg | >800Kg |

| FZG A/S Test | N.A. | >12 | >12 | >12 | >12 | >12 | >12 |

| Solid Lubricants | Special solid additives | Graphite | Graphite | Graphite | Graphite | Graphite | Graphite |

| Working Temp. | N.A. | -15~130 | -10~150 | -15~130 | -10~140 | -15~130 | -18~130 |

| Product | G.BESLUX CROWN M FLUID | G.BESLUX CROWN M FLUID PLUS | G.BESLUX CROWN H-3000 | G.BESLUX CROWN H-6000 | G.BESLUX CROWN HEAVY MILL | G.BESLUX HEAVY MILL PLUS II |

| Color | Black | Black | Black | Black | Black | Black |

| Base Oil | Semi-synthetic | Semi-synthetic | Semi-synthetic | Semi-synthetic | Semi-synthetic | Semi-synthetic |

| Thickener | Aluminium complex | Aluminium complex | Aluminium complex | Aluminium complex | Aluminium complex | Aluminium complex |

| NLGI Grade | 000 | 000 | 0 | 00/000 | 00 | 00 |

| Drop Point | >200°C | >200°C | >200°C | >200°C | >200°C | >200°C |

| Welding Load | >800Kg | >800Kg | >800Kg | >800Kg | >800Kg | >800Kg |

| FZG A/S Test | >12 | >12 | >12 | >12 | >12 | >12 |

| Solid Lubricants | Graphite | Special graphite | Graphite | Graphite | Graphite | Graphite |

| Working Temp. | -15~130 | -15~130 | -10/150 | 0~150 | 0~150 | 5~120 (short 140) |

* The above data are typical laboratory data, and each batch is subject to the oil analysis report.

* NLGI 000 grade products are recommended for immersion lubrication.

BESLUX CROWN OG PLUS Neat Oil OG Type

| Product | BESLUX CROWN 150 OG PLUS | BESLUX CROWN 320 OG PLUS | BESLUX CROWN 500 OG PLUS | BESLUX CROWN 1000 OG PLUS | BESLUX CROWN 1200 OG PLUS | G. BESLUX WHITE OG-320 | G. BESLUX WHITE OG-680 |

| Color | Light brown | Light brown | Light yellow | Light yellow | Light yellow | Beige | Beige |

| Base Oil | Synthetic | Synthetic | Synthetic | Synthetic | Synthetic | Synthetic | Synthetic |

| NLGI Grade | N.A. | N.A. | N.A. | N.A. | N.A. | 00 | 00 |

| Drop Point | >220°C | >220°C | >220°C | >220°C | >220°C | >200°C | >200°C |

| Welding Load | >800Kg | >800Kg | >800Kg | >800Kg | >800Kg | >800Kg | >800Kg |

| FZG A/S Test | >12 | >12 | >12 | >12 | >12 | >12 | >12 |

| Solid Lubricants | N.A. | N.A. | N.A. | N.A. | N.A. | White graphite + Special additives | White graphite + Special additives |

| Working Temp. | 15 ~ 120 | 15 ~ 120 | 15 ~ 120 | 15 ~ 120 | 15 ~ 120 | 15 ~ 120 | 15 ~ 120 |